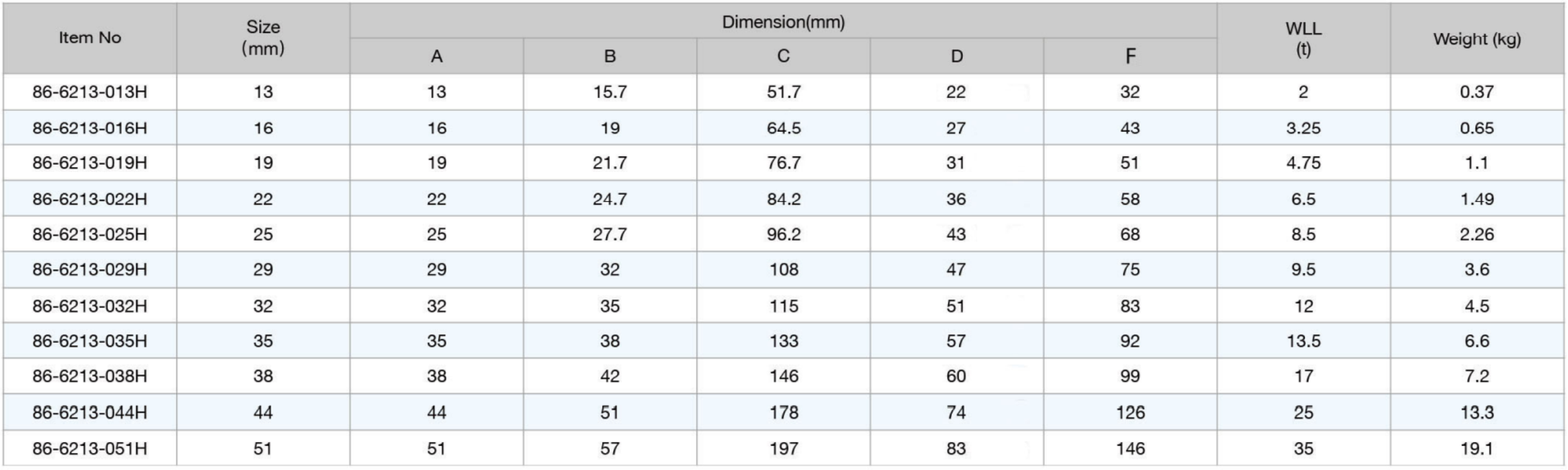

SQUARE HEAD PIN ANCHOR SHACKLES

• Square Head Hole Pin Anchor Shackles

Maximum Proof Load is 2 times the working load limit.

Minimum Ultimate Load is 6 times the working load limit.

• Capacities 2 thru 35 metric tons.

• Forged - Quenched and Tempered, with alloy pins.

• Working Load Limit permanently shown on every shackle.

• Hot Dip galvanized or self colored.

• Fatigue rated.

• Test and mill Certificates are available upon request.

A shackle is a u-shaped, load-bearing connecting device designed to be used with a removable pin. Shackles can be used in a number of different rigging and load securement applications to connect different types of lifting slings, chain, or rope to an object or to each other。

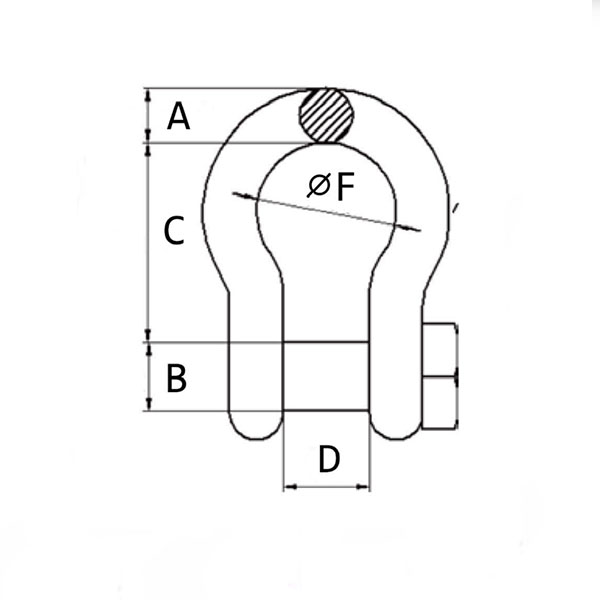

There are four parts of shackle: bow pin, ear, shoulder. Bow – the curved portion of the shackle body opposite the pin—often referred to as the bail, body, dee, or bowl Ears – portion of the shackle body that support the shackle pin Pin – a steel bolt made to span the two shackle ears Shoulder – the part of the pin that makes contact against the ear when the pin is fully threaded or engaged There are many different types of shackles

Shackle Bow Types: Anchor Shackles(Bow shackles) vs. Chain Shackles (D Shackles)

Shackle Pin Types: Screw Pin vs. Bolt Type vs. Round Pin.

U.S. Anchor shackles /U.S.Screw pin anchor shackles/ G209:

On a screw pin shackle, a threaded pin is inserted through the ears and tightened down. Screw pin shackles are quick and easy to connect and disconnect

so they’re convenient for rigging that is used for “pick and place” applications or when slings and other hardware are often changed out.

Screw pin shackles are not recommended for permanent or long-term installations.

Screw pin shackles can be used in applications where side loading is present, and with multi-leg sling assemblies. However, reduction to the WLL must be accounted for when used in a side-loading situation.

Shackle Material :Carbon Steel Shackles;Alloy Steel Shackles ;Stainless Steel For type IVA carbon steel shackles, steel to be in accordance with ASTM A576 or equivalent. Heat treatment is required to specifified physical properties.

Shackles, mechanical coupling links, connecting links and swivels to be forged. For alloy shackles and mechanical coupling links, steel to be alloy type in accordance with ASTM A322, ASTM A304, ASTM A752 or equivalent. Heat treatment is required to specifified physical properties.

Dayu carbon shackles have the highest design factor (6 to 1) in the industry and alloy shackles a minimum of 5 to 1 Close tolerance holes and concentric pins with good surface fifinishes are provided by Dayu and are proven to provide improved fatigue life in actual use Forged - Quenched and Tempered

All Dayu shackle bows and pins are quenched and tempered, which enhances their performance under cold temperatures and adverse fifield conditions .And it provide the tensile strength, ductility, impact, and fatigue properties that are essential if they are to perform time after time in adverse conditions.

The proper application of shackles requires that the correct type and size of shackle be used.

The shackle’s Working Load Limit, its size, a code, and the manufacturer’s name should be clearly marked in the bow. Working Load Limit and grade “6” permanently... shown on every shackle The proper application of shackles requires that the correct type and size of shackle be used.

The shackle’s Working Load Limit, its size, a code, and the manufacturer’s name should be clearly marked in the bow.

The “Working Load Limit”is the maximum load that shall be applied in direct tension to an undamaged straight length of shackles Hot Dip galvanized or self- colored. Hot dip galvanized coating is produced by immersing steel into molten zinc. The zinc alloys with the surface of the steel to create a protective barrier between the atmosphere and the steel. Hot dip galvanizing to be in accordance with ASTM A153/A153M, class B or equivalent.

Powder coating is applied with an electrostatic gun as a dry powder before being heat cured in an oven environment.

Certifification: Certifification to world class standards is available upon special request at the time of order; American Bureau of Shipping, Lloyds Register of Shipping, Det Norske Veritas, American Petroleum Institute, RINA, Nuclear Regulatory Commission, and several other worldwide standards.

From there, you can partner with a reputable rigging manufacturer , to determine the best type of shackles to use for your application. This will ensure that the design of the shackle and its Working Load Limit is adequate for the lifts you’ll be performing.

Dayu Rigging is the professional rigging hardware manufacturer We are mainly engaged producing shackles, hooks, turnbuckles, swivels, thimble… more than 20years.We can quote and fabricate sling assemblies or get you the individual slings and hardware that you need to put them together yourself. And We offer a full inventory of hooks, shackles, and other rigging hardware.

We continue to innovate and expand our rigging portfolio to meet industry needs and give customers the products they need for their unique and challenging applications.

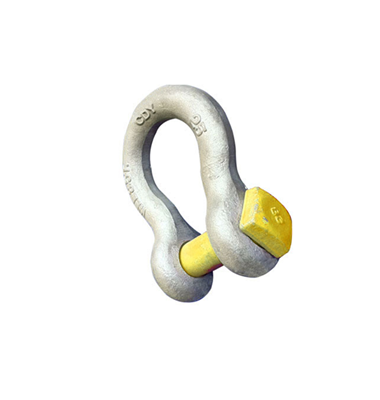

Parameter